Product Description

Tractor Pto Driveshaft Driveline Factory Hollow Spline Cardan Adapter Universal Joint Yoke Flexible Front Prop Rear CV Axle Propeller Automobile Drive Shaft

Product Description

Agricultural truck universal joint steering

PTO Shaft

| Function of PTO Shaft | Drive Shaft Parts & Power Transmission |

| Usage of PTO Shaft | Kinds of Tractors & Farm Implements |

| Yoke Types for PTO Shaft | Double push pin, Bolt pins, Split pins, Pushpin, Quick release, Ball attachment, Collar….. |

| Processing Of Yoke | Forging |

| PTO Shaft Plastic Cover | YW; BW; YS; BS; Etc |

| Colors of PTO Shaft | Green; Orange; Yellow; Black Ect. |

| PTO Shaft Series | T1-T10; L1-L6;S6-S10;10HP-150HP with SA,RA,SB,SFF,WA,CV Etc |

| Tube Types for PTO Shaft | Lemon, Triangular, Star, Square, Hexangular, Spline, Special Ect |

| Processing Of Tube | Cold drawn |

| Spline Types for PTO Shaft | 1 1/8″ Z6;1 3/8″ Z6; 1 3/8″ Z21 ;1 3/4″ Z20; 1 3/4″ Z6; 8-38*32*6 8-42*36*7; 8-48*42*8; |

We also sell accessories for the pto shaft, including :

Yoke: CV socket yoke, CV weld yoke, flange yoke, end yoke, weld yoke, slip yoke

CV center housing, tube, spline, CV socket flange, u-joint, dust cap

Light vehicle drive line

Our products can be used for transmission shafts of the following brands

Toyota, Mitsubishi, Nissan, Isu zu, Suzuki, Dafa, Honda, Hyundai, Mazda, Fiat, Re nault, Kia, Dacia, Ford. Dodge, Land Rover, Peu geot, Volkswagen Audi, BMW Benz Volvo, Russian models

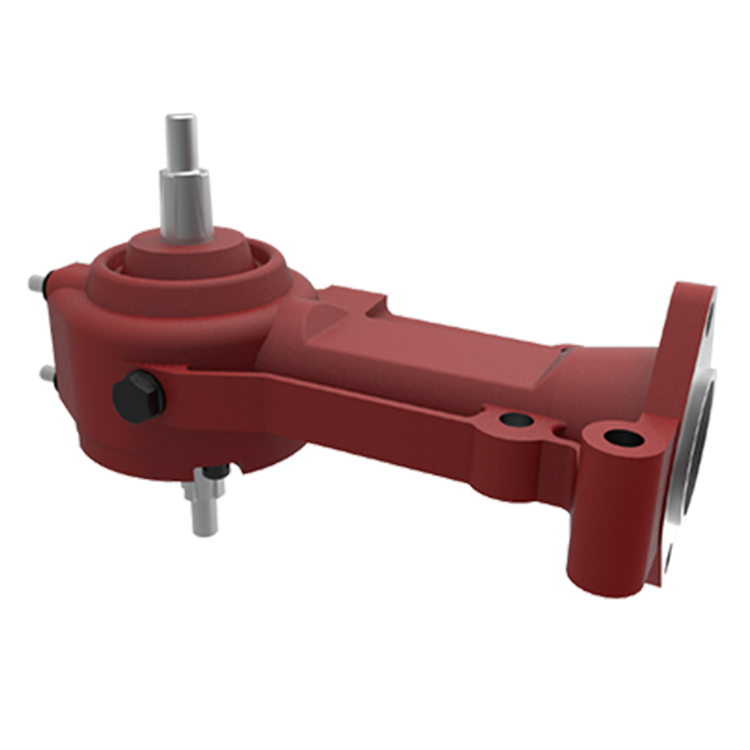

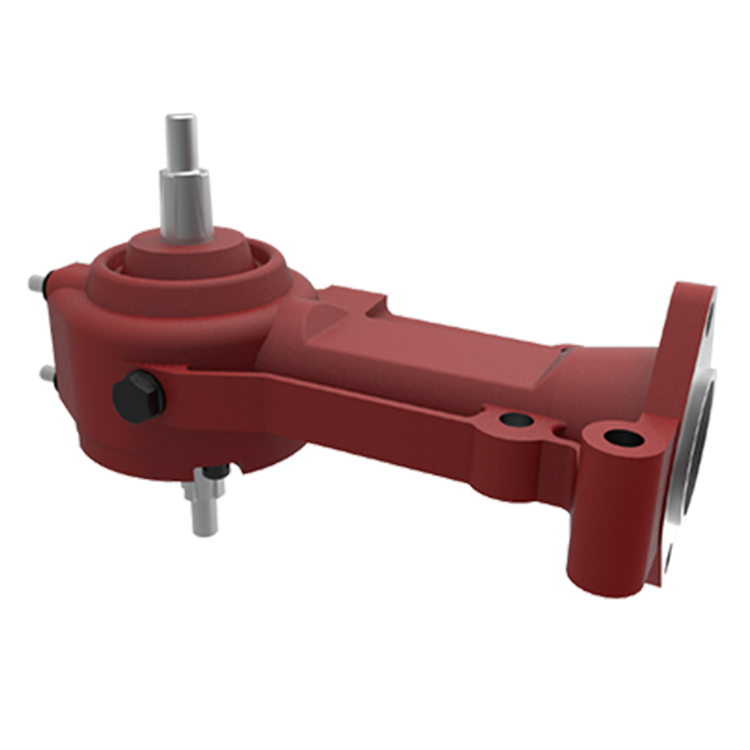

Gear shaft

Company Profile

Related Products

Application:

Company information:

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 38/Piece

1 Piece(Min.Order) | |

|---|

Are there any limitations or disadvantages associated with drive shafts?

While drive shafts are widely used and offer several advantages, they also have certain limitations and disadvantages that should be considered. Here’s a detailed explanation of the limitations and disadvantages associated with drive shafts:

1. Length and Misalignment Constraints:

Drive shafts have a maximum practical length due to factors such as material strength, weight considerations, and the need to maintain rigidity and minimize vibrations. Longer drive shafts can be prone to increased bending and torsional deflection, leading to reduced efficiency and potential driveline vibrations. Additionally, drive shafts require proper alignment between the driving and driven components. Misalignment can cause increased wear, vibrations, and premature failure of the drive shaft or its associated components.

2. Limited Operating Angles:

Drive shafts, especially those using U-joints, have limitations on operating angles. U-joints are typically designed to operate within specific angular ranges, and operating beyond these limits can result in reduced efficiency, increased vibrations, and accelerated wear. In applications requiring large operating angles, constant velocity (CV) joints are often used to maintain a constant speed and accommodate greater angles. However, CV joints may introduce higher complexity and cost compared to U-joints.

3. Maintenance Requirements:

Drive shafts require regular maintenance to ensure optimal performance and reliability. This includes periodic inspection, lubrication of joints, and balancing if necessary. Failure to perform routine maintenance can lead to increased wear, vibrations, and potential driveline issues. Maintenance requirements should be considered in terms of time and resources when using drive shafts in various applications.

4. Noise and Vibration:

Drive shafts can generate noise and vibrations, especially at high speeds or when operating at certain resonant frequencies. Imbalances, misalignment, worn joints, or other factors can contribute to increased noise and vibrations. These vibrations may affect the comfort of vehicle occupants, contribute to component fatigue, and require additional measures such as dampers or vibration isolation systems to mitigate their effects.

5. Weight and Space Constraints:

Drive shafts add weight to the overall system, which can be a consideration in weight-sensitive applications, such as automotive or aerospace industries. Additionally, drive shafts require physical space for installation. In compact or tightly packaged equipment or vehicles, accommodating the necessary drive shaft length and clearances can be challenging, requiring careful design and integration considerations.

6. Cost Considerations:

Drive shafts, depending on their design, materials, and manufacturing processes, can involve significant costs. Customized or specialized drive shafts tailored to specific equipment requirements may incur higher expenses. Additionally, incorporating advanced joint configurations, such as CV joints, can add complexity and cost to the drive shaft system.

7. Inherent Power Loss:

Drive shafts transmit power from the driving source to the driven components, but they also introduce some inherent power loss due to friction, bending, and other factors. This power loss can reduce overall system efficiency, particularly in long drive shafts or applications with high torque requirements. It is important to consider power loss when determining the appropriate drive shaft design and specifications.

8. Limited Torque Capacity:

While drive shafts can handle a wide range of torque loads, there are limits to their torque capacity. Exceeding the maximum torque capacity of a drive shaft can lead to premature failure, resulting in downtime and potential damage to other driveline components. It is crucial to select a drive shaft with sufficient torque capacity for the intended application.

Despite these limitations and disadvantages, drive shafts remain a widely used and effective means of power transmission in various industries. Manufacturers continuously work to address these limitations through advancements in materials, design techniques, joint configurations, and balancing processes. By carefully considering the specific application requirements and potential drawbacks, engineers and designers can mitigate the limitations and maximize the benefits of drive shafts in their respective systems.

How do drive shafts enhance the performance of automobiles and trucks?

Drive shafts play a significant role in enhancing the performance of automobiles and trucks. They contribute to various aspects of vehicle performance, including power delivery, traction, handling, and overall efficiency. Here’s a detailed explanation of how drive shafts enhance the performance of automobiles and trucks:

1. Power Delivery:

Drive shafts are responsible for transferring power from the engine to the wheels, enabling the vehicle to move forward. By efficiently transmitting power without significant losses, drive shafts ensure that the engine’s power is effectively utilized, resulting in improved acceleration and overall performance. Well-designed drive shafts with minimal power loss contribute to the vehicle’s ability to deliver power to the wheels efficiently.

2. Torque Transfer:

Drive shafts facilitate the transfer of torque from the engine to the wheels. Torque is the rotational force that drives the vehicle forward. High-quality drive shafts with proper torque conversion capabilities ensure that the torque generated by the engine is effectively transmitted to the wheels. This enhances the vehicle’s ability to accelerate quickly, tow heavy loads, and climb steep gradients, thereby improving overall performance.

3. Traction and Stability:

Drive shafts contribute to the traction and stability of automobiles and trucks. They transmit power to the wheels, allowing them to exert force on the road surface. This enables the vehicle to maintain traction, especially during acceleration or when driving on slippery or uneven terrain. The efficient power delivery through the drive shafts enhances the vehicle’s stability by ensuring balanced power distribution to all wheels, improving control and handling.

4. Handling and Maneuverability:

Drive shafts have an impact on the handling and maneuverability of vehicles. They help establish a direct connection between the engine and the wheels, allowing for precise control and responsive handling. Well-designed drive shafts with minimal play or backlash contribute to a more direct and immediate response to driver inputs, enhancing the vehicle’s agility and maneuverability.

5. Weight Reduction:

Drive shafts can contribute to weight reduction in automobiles and trucks. Lightweight drive shafts made from materials such as aluminum or carbon fiber-reinforced composites reduce the overall weight of the vehicle. The reduced weight improves the power-to-weight ratio, resulting in better acceleration, handling, and fuel efficiency. Additionally, lightweight drive shafts reduce the rotational mass, allowing the engine to rev up more quickly, further enhancing performance.

6. Mechanical Efficiency:

Efficient drive shafts minimize energy losses during power transmission. By incorporating features such as high-quality bearings, low-friction seals, and optimized lubrication, drive shafts reduce friction and minimize power losses due to internal resistance. This enhances the mechanical efficiency of the drivetrain system, allowing more power to reach the wheels and improving overall vehicle performance.

7. Performance Upgrades:

Drive shaft upgrades can be a popular performance enhancement for enthusiasts. Upgraded drive shafts, such as those made from stronger materials or with enhanced torque capacity, can handle higher power outputs from modified engines. These upgrades allow for increased performance, such as improved acceleration, higher top speeds, and better overall driving dynamics.

8. Compatibility with Performance Modifications:

Performance modifications, such as engine upgrades, increased power output, or changes to the drivetrain system, often require compatible drive shafts. Drive shafts designed to handle higher torque loads or adapt to modified drivetrain configurations ensure optimal performance and reliability. They enable the vehicle to effectively harness the increased power and torque, resulting in improved performance and responsiveness.

9. Durability and Reliability:

Robust and well-maintained drive shafts contribute to the durability and reliability of automobiles and trucks. They are designed to withstand the stresses and loads associated with power transmission. High-quality materials, appropriate balancing, and regular maintenance help ensure that drive shafts operate smoothly, minimizing the risk of failures or performance issues. Reliable drive shafts enhance the overall performance by providing consistent power delivery and minimizing downtime.

10. Compatibility with Advanced Technologies:

Drive shafts are evolving in tandem with advancements in vehicle technologies. They are increasingly being integrated with advanced systems such as hybrid powertrains, electric motors, and regenerative braking. Drive shafts designed to work seamlessly with these technologies maximize their efficiency and performance benefits, contributing to improved overall vehicle performance.

In summary, drive shafts enhance the performance of automobiles and trucks by optimizing power delivery, facilitating torque transfer, improving traction and stability, enhancing handling and maneuverability, reducing weight, increasing mechanical efficiency,and enabling compatibility with performance upgrades and advanced technologies. They play a crucial role in ensuring efficient power transmission, responsive acceleration, precise handling, and overall improved performance of vehicles.

What benefits do drive shafts offer for different types of vehicles and equipment?

Drive shafts offer several benefits for different types of vehicles and equipment. They play a crucial role in power transmission and contribute to the overall performance, efficiency, and functionality of various systems. Here’s a detailed explanation of the benefits that drive shafts provide:

1. Efficient Power Transmission:

Drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. By connecting the engine or motor to the driven system, drive shafts efficiently transfer rotational power, allowing vehicles and equipment to perform their intended functions. This efficient power transmission ensures that the power generated by the engine is effectively utilized, optimizing the overall performance and productivity of the system.

2. Versatility:

Drive shafts offer versatility in their applications. They are used in various types of vehicles, including cars, trucks, motorcycles, and off-road vehicles. Additionally, drive shafts are employed in a wide range of equipment and machinery, such as agricultural machinery, construction equipment, industrial machinery, and marine vessels. The ability to adapt to different types of vehicles and equipment makes drive shafts a versatile component for power transmission.

3. Torque Handling:

Drive shafts are designed to handle high levels of torque. Torque is the rotational force generated by the engine or power source. Drive shafts are engineered to efficiently transmit this torque without excessive twisting or bending. By effectively handling torque, drive shafts ensure that the power generated by the engine is reliably transferred to the wheels or driven components, enabling vehicles and equipment to overcome resistance, such as heavy loads or challenging terrains.

4. Flexibility and Compensation:

Drive shafts provide flexibility and compensation for angular movement and misalignment. In vehicles, drive shafts accommodate the movement of the suspension system, allowing the wheels to move up and down independently. This flexibility ensures a constant power transfer even when the vehicle encounters uneven terrain. Similarly, in machinery, drive shafts compensate for misalignment between the engine or motor and the driven components, ensuring smooth power transmission and preventing excessive stress on the drivetrain.

5. Weight Reduction:

Drive shafts contribute to weight reduction in vehicles and equipment. Compared to other forms of power transmission, such as belt drives or chain drives, drive shafts are typically lighter in weight. This reduction in weight helps improve fuel efficiency in vehicles and reduces the overall weight of equipment, leading to enhanced maneuverability and increased payload capacity. Additionally, lighter drive shafts contribute to a better power-to-weight ratio, resulting in improved performance and acceleration.

6. Durability and Longevity:

Drive shafts are designed to be durable and long-lasting. They are constructed using materials such as steel or aluminum, which offer high strength and resistance to wear and fatigue. Drive shafts undergo rigorous testing and quality control measures to ensure their reliability and longevity. Proper maintenance, including lubrication and regular inspections, further enhances their durability. The robust construction and long lifespan of drive shafts contribute to the overall reliability and cost-effectiveness of vehicles and equipment.

7. Safety:

Drive shafts incorporate safety features to protect operators and bystanders. In vehicles, drive shafts are often enclosed within a protective tube or housing, preventing contact with moving parts and reducing the risk of injury in the event of a failure. Similarly, in machinery, safety shields or guards are commonly installed around exposed drive shafts to minimize the potential hazards associated with rotating components. These safety measures ensure the well-being of individuals operating or working in proximity to vehicles and equipment.

In summary, drive shafts offer several benefits for different types of vehicles and equipment. They enable efficient power transmission, provide versatility in various applications, handle torque effectively, offer flexibility and compensation, contribute to weight reduction, ensure durability and longevity, and incorporate safety features. By providing these advantages, drive shafts enhance the performance, efficiency, reliability, and safety of vehicles and equipment across a wide range of industries.

editor by CX 2024-02-17

China Best Sales Tractor Pto Driveshaft Driveline Factory Hollow Spline Cardan Adapter Universal Joint Yoke Flexible Front Prop Rear CV Axle Propeller Automobile Drive Shaft

Product Description

Tractor Pto Driveshaft Driveline Factory Hollow Spline Cardan Adapter Universal Joint Yoke Flexible Front Prop Rear CV Axle Propeller Automobile Drive Shaft

Product Description

Agricultural truck universal joint steering

PTO Shaft

| Function of PTO Shaft | Drive Shaft Parts & Power Transmission |

| Usage of PTO Shaft | Kinds of Tractors & Farm Implements |

| Yoke Types for PTO Shaft | Double push pin, Bolt pins, Split pins, Pushpin, Quick release, Ball attachment, Collar….. |

| Processing Of Yoke | Forging |

| PTO Shaft Plastic Cover | YW; BW; YS; BS; Etc |

| Colors of PTO Shaft | Green; Orange; Yellow; Black Ect. |

| PTO Shaft Series | T1-T10; L1-L6;S6-S10;10HP-150HP with SA,RA,SB,SFF,WA,CV Etc |

| Tube Types for PTO Shaft | Lemon, Triangular, Star, Square, Hexangular, Spline, Special Ect |

| Processing Of Tube | Cold drawn |

| Spline Types for PTO Shaft | 1 1/8″ Z6;1 3/8″ Z6; 1 3/8″ Z21 ;1 3/4″ Z20; 1 3/4″ Z6; 8-38*32*6 8-42*36*7; 8-48*42*8; |

We also sell accessories for the pto shaft, including :

Yoke: CV socket yoke, CV weld yoke, flange yoke, end yoke, weld yoke, slip yoke

CV center housing, tube, spline, CV socket flange, u-joint, dust cap

Light vehicle drive line

Our products can be used for transmission shafts of the following brands

Toyota, Mitsubishi, Nissan, Isu zu, Suzuki, Dafa, Honda, Hyundai, Mazda, Fiat, Re nault, Kia, Dacia, Ford. Dodge, Land Rover, Peu geot, Volkswagen Audi, BMW Benz Volvo, Russian models

Gear shaft

Company Profile

Related Products

Application:

Company information:

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 38/Piece

1 Piece(Min.Order) | |

|---|

Are there any limitations or disadvantages associated with drive shafts?

While drive shafts are widely used and offer several advantages, they also have certain limitations and disadvantages that should be considered. Here’s a detailed explanation of the limitations and disadvantages associated with drive shafts:

1. Length and Misalignment Constraints:

Drive shafts have a maximum practical length due to factors such as material strength, weight considerations, and the need to maintain rigidity and minimize vibrations. Longer drive shafts can be prone to increased bending and torsional deflection, leading to reduced efficiency and potential driveline vibrations. Additionally, drive shafts require proper alignment between the driving and driven components. Misalignment can cause increased wear, vibrations, and premature failure of the drive shaft or its associated components.

2. Limited Operating Angles:

Drive shafts, especially those using U-joints, have limitations on operating angles. U-joints are typically designed to operate within specific angular ranges, and operating beyond these limits can result in reduced efficiency, increased vibrations, and accelerated wear. In applications requiring large operating angles, constant velocity (CV) joints are often used to maintain a constant speed and accommodate greater angles. However, CV joints may introduce higher complexity and cost compared to U-joints.

3. Maintenance Requirements:

Drive shafts require regular maintenance to ensure optimal performance and reliability. This includes periodic inspection, lubrication of joints, and balancing if necessary. Failure to perform routine maintenance can lead to increased wear, vibrations, and potential driveline issues. Maintenance requirements should be considered in terms of time and resources when using drive shafts in various applications.

4. Noise and Vibration:

Drive shafts can generate noise and vibrations, especially at high speeds or when operating at certain resonant frequencies. Imbalances, misalignment, worn joints, or other factors can contribute to increased noise and vibrations. These vibrations may affect the comfort of vehicle occupants, contribute to component fatigue, and require additional measures such as dampers or vibration isolation systems to mitigate their effects.

5. Weight and Space Constraints:

Drive shafts add weight to the overall system, which can be a consideration in weight-sensitive applications, such as automotive or aerospace industries. Additionally, drive shafts require physical space for installation. In compact or tightly packaged equipment or vehicles, accommodating the necessary drive shaft length and clearances can be challenging, requiring careful design and integration considerations.

6. Cost Considerations:

Drive shafts, depending on their design, materials, and manufacturing processes, can involve significant costs. Customized or specialized drive shafts tailored to specific equipment requirements may incur higher expenses. Additionally, incorporating advanced joint configurations, such as CV joints, can add complexity and cost to the drive shaft system.

7. Inherent Power Loss:

Drive shafts transmit power from the driving source to the driven components, but they also introduce some inherent power loss due to friction, bending, and other factors. This power loss can reduce overall system efficiency, particularly in long drive shafts or applications with high torque requirements. It is important to consider power loss when determining the appropriate drive shaft design and specifications.

8. Limited Torque Capacity:

While drive shafts can handle a wide range of torque loads, there are limits to their torque capacity. Exceeding the maximum torque capacity of a drive shaft can lead to premature failure, resulting in downtime and potential damage to other driveline components. It is crucial to select a drive shaft with sufficient torque capacity for the intended application.

Despite these limitations and disadvantages, drive shafts remain a widely used and effective means of power transmission in various industries. Manufacturers continuously work to address these limitations through advancements in materials, design techniques, joint configurations, and balancing processes. By carefully considering the specific application requirements and potential drawbacks, engineers and designers can mitigate the limitations and maximize the benefits of drive shafts in their respective systems.

How do drive shafts handle variations in load and vibration during operation?

Drive shafts are designed to handle variations in load and vibration during operation by employing various mechanisms and features. These mechanisms help ensure smooth power transmission, minimize vibrations, and maintain the structural integrity of the drive shaft. Here’s a detailed explanation of how drive shafts handle load and vibration variations:

1. Material Selection and Design:

Drive shafts are typically made from materials with high strength and stiffness, such as steel alloys or composite materials. The material selection and design take into account the anticipated loads and operating conditions of the application. By using appropriate materials and optimizing the design, drive shafts can withstand the expected variations in load without experiencing excessive deflection or deformation.

2. Torque Capacity:

Drive shafts are designed with a specific torque capacity that corresponds to the expected loads. The torque capacity takes into account factors such as the power output of the driving source and the torque requirements of the driven components. By selecting a drive shaft with sufficient torque capacity, variations in load can be accommodated without exceeding the drive shaft’s limits and risking failure or damage.

3. Dynamic Balancing:

During the manufacturing process, drive shafts can undergo dynamic balancing. Imbalances in the drive shaft can result in vibrations during operation. Through the balancing process, weights are strategically added or removed to ensure that the drive shaft spins evenly and minimizes vibrations. Dynamic balancing helps to mitigate the effects of load variations and reduces the potential for excessive vibrations in the drive shaft.

4. Dampers and Vibration Control:

Drive shafts can incorporate dampers or vibration control mechanisms to further minimize vibrations. These devices are typically designed to absorb or dissipate vibrations that may arise from load variations or other factors. Dampers can be in the form of torsional dampers, rubber isolators, or other vibration-absorbing elements strategically placed along the drive shaft. By managing and attenuating vibrations, drive shafts ensure smooth operation and enhance overall system performance.

5. CV Joints:

Constant Velocity (CV) joints are often used in drive shafts to accommodate variations in operating angles and to maintain a constant speed. CV joints allow the drive shaft to transmit power even when the driving and driven components are at different angles. By accommodating variations in operating angles, CV joints help minimize the impact of load variations and reduce potential vibrations that may arise from changes in the driveline geometry.

6. Lubrication and Maintenance:

Proper lubrication and regular maintenance are essential for drive shafts to handle load and vibration variations effectively. Lubrication helps reduce friction between moving parts, minimizing wear and heat generation. Regular maintenance, including inspection and lubrication of joints, ensures that the drive shaft remains in optimal condition, reducing the risk of failure or performance degradation due to load variations.

7. Structural Rigidity:

Drive shafts are designed to have sufficient structural rigidity to resist bending and torsional forces. This rigidity helps maintain the integrity of the drive shaft when subjected to load variations. By minimizing deflection and maintaining structural integrity, the drive shaft can effectively transmit power and handle variations in load without compromising performance or introducing excessive vibrations.

8. Control Systems and Feedback:

In some applications, drive shafts may be equipped with control systems that actively monitor and adjust parameters such as torque, speed, and vibration. These control systems use sensors and feedback mechanisms to detect variations in load or vibrations and make real-time adjustments to optimize performance. By actively managing load variations and vibrations, drive shafts can adapt to changing operating conditions and maintain smooth operation.

In summary, drive shafts handle variations in load and vibration during operation through careful material selection and design, torque capacity considerations, dynamic balancing, integration of dampers and vibration control mechanisms, utilization of CV joints, proper lubrication and maintenance, structural rigidity, and, in some cases, control systems and feedback mechanisms. By incorporating these features and mechanisms, drive shafts ensure reliable and efficient power transmission while minimizing the impact of load variations and vibrations on overall system performance.

What benefits do drive shafts offer for different types of vehicles and equipment?

Drive shafts offer several benefits for different types of vehicles and equipment. They play a crucial role in power transmission and contribute to the overall performance, efficiency, and functionality of various systems. Here’s a detailed explanation of the benefits that drive shafts provide:

1. Efficient Power Transmission:

Drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. By connecting the engine or motor to the driven system, drive shafts efficiently transfer rotational power, allowing vehicles and equipment to perform their intended functions. This efficient power transmission ensures that the power generated by the engine is effectively utilized, optimizing the overall performance and productivity of the system.

2. Versatility:

Drive shafts offer versatility in their applications. They are used in various types of vehicles, including cars, trucks, motorcycles, and off-road vehicles. Additionally, drive shafts are employed in a wide range of equipment and machinery, such as agricultural machinery, construction equipment, industrial machinery, and marine vessels. The ability to adapt to different types of vehicles and equipment makes drive shafts a versatile component for power transmission.

3. Torque Handling:

Drive shafts are designed to handle high levels of torque. Torque is the rotational force generated by the engine or power source. Drive shafts are engineered to efficiently transmit this torque without excessive twisting or bending. By effectively handling torque, drive shafts ensure that the power generated by the engine is reliably transferred to the wheels or driven components, enabling vehicles and equipment to overcome resistance, such as heavy loads or challenging terrains.

4. Flexibility and Compensation:

Drive shafts provide flexibility and compensation for angular movement and misalignment. In vehicles, drive shafts accommodate the movement of the suspension system, allowing the wheels to move up and down independently. This flexibility ensures a constant power transfer even when the vehicle encounters uneven terrain. Similarly, in machinery, drive shafts compensate for misalignment between the engine or motor and the driven components, ensuring smooth power transmission and preventing excessive stress on the drivetrain.

5. Weight Reduction:

Drive shafts contribute to weight reduction in vehicles and equipment. Compared to other forms of power transmission, such as belt drives or chain drives, drive shafts are typically lighter in weight. This reduction in weight helps improve fuel efficiency in vehicles and reduces the overall weight of equipment, leading to enhanced maneuverability and increased payload capacity. Additionally, lighter drive shafts contribute to a better power-to-weight ratio, resulting in improved performance and acceleration.

6. Durability and Longevity:

Drive shafts are designed to be durable and long-lasting. They are constructed using materials such as steel or aluminum, which offer high strength and resistance to wear and fatigue. Drive shafts undergo rigorous testing and quality control measures to ensure their reliability and longevity. Proper maintenance, including lubrication and regular inspections, further enhances their durability. The robust construction and long lifespan of drive shafts contribute to the overall reliability and cost-effectiveness of vehicles and equipment.

7. Safety:

Drive shafts incorporate safety features to protect operators and bystanders. In vehicles, drive shafts are often enclosed within a protective tube or housing, preventing contact with moving parts and reducing the risk of injury in the event of a failure. Similarly, in machinery, safety shields or guards are commonly installed around exposed drive shafts to minimize the potential hazards associated with rotating components. These safety measures ensure the well-being of individuals operating or working in proximity to vehicles and equipment.

In summary, drive shafts offer several benefits for different types of vehicles and equipment. They enable efficient power transmission, provide versatility in various applications, handle torque effectively, offer flexibility and compensation, contribute to weight reduction, ensure durability and longevity, and incorporate safety features. By providing these advantages, drive shafts enhance the performance, efficiency, reliability, and safety of vehicles and equipment across a wide range of industries.

editor by CX 2024-01-25

China Standard Tractor Pto Driveshaft Driveline Factory Hollow Spline Cardan Adapter Universal Joint Yoke Flexible Front Prop Rear CV Axle Propeller Automobile Drive Shaft

Product Description

Tractor Pto Driveshaft Driveline Factory Hollow Spline Cardan Adapter Universal Joint Yoke Flexible Front Prop Rear CV Axle Propeller Automobile Drive Shaft

Product Description

Agricultural truck universal joint steering

PTO Shaft

| Function of PTO Shaft | Drive Shaft Parts & Power Transmission |

| Usage of PTO Shaft | Kinds of Tractors & Farm Implements |

| Yoke Types for PTO Shaft | Double push pin, Bolt pins, Split pins, Pushpin, Quick release, Ball attachment, Collar….. |

| Processing Of Yoke | Forging |

| PTO Shaft Plastic Cover | YW; BW; YS; BS; Etc |

| Colors of PTO Shaft | Green; Orange; Yellow; Black Ect. |

| PTO Shaft Series | T1-T10; L1-L6;S6-S10;10HP-150HP with SA,RA,SB,SFF,WA,CV Etc |

| Tube Types for PTO Shaft | Lemon, Triangular, Star, Square, Hexangular, Spline, Special Ect |

| Processing Of Tube | Cold drawn |

| Spline Types for PTO Shaft | 1 1/8″ Z6;1 3/8″ Z6; 1 3/8″ Z21 ;1 3/4″ Z20; 1 3/4″ Z6; 8-38*32*6 8-42*36*7; 8-48*42*8; |

We also sell accessories for the pto shaft, including :

Yoke: CV socket yoke, CV weld yoke, flange yoke, end yoke, weld yoke, slip yoke

CV center housing, tube, spline, CV socket flange, u-joint, dust cap

Light vehicle drive line

Our products can be used for transmission shafts of the following brands

Toyota, Mitsubishi, Nissan, Isu zu, Suzuki, Dafa, Honda, Hyundai, Mazda, Fiat, Re nault, Kia, Dacia, Ford. Dodge, Land Rover, Peu geot, Volkswagen Audi, BMW Benz Volvo, Russian models

Gear shaft

Company Profile

Related Products

Application:

Company information:

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 38/Piece

1 Piece(Min.Order) | |

|---|

How do drive shafts ensure efficient power transfer while maintaining balance?

Drive shafts employ various mechanisms to ensure efficient power transfer while maintaining balance. Efficient power transfer refers to the ability of the drive shaft to transmit rotational power from the source (such as an engine) to the driven components (such as wheels or machinery) with minimal energy loss. Balancing, on the other hand, involves minimizing vibrations and eliminating any uneven distribution of mass that can cause disturbances during operation. Here’s an explanation of how drive shafts achieve both efficient power transfer and balance:

1. Material Selection:

The material selection for drive shafts is crucial for maintaining balance and ensuring efficient power transfer. Drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, stiffness, and durability. These materials have excellent dimensional stability and can withstand the torque loads encountered during operation. By using high-quality materials, drive shafts can minimize deformation, flexing, and imbalances that could compromise power transmission and generate vibrations.

2. Design Considerations:

The design of the drive shaft plays a significant role in both power transfer efficiency and balance. Drive shafts are engineered to have appropriate dimensions, including diameter and wall thickness, to handle the anticipated torque loads without excessive deflection or vibration. The design also considers factors such as the length of the drive shaft, the number and type of joints (such as universal joints or constant velocity joints), and the use of balancing weights. By carefully designing the drive shaft, manufacturers can achieve optimal power transfer efficiency while minimizing the potential for imbalance-induced vibrations.

3. Balancing Techniques:

Balance is crucial for drive shafts as any imbalance can cause vibrations, noise, and accelerated wear. To maintain balance, drive shafts undergo various balancing techniques during the manufacturing process. Static and dynamic balancing methods are employed to ensure that the mass distribution along the drive shaft is uniform. Static balancing involves adding counterweights at specific locations to offset any weight imbalances. Dynamic balancing is performed by spinning the drive shaft at high speeds and measuring any vibrations. If imbalances are detected, additional adjustments are made to achieve a balanced state. These balancing techniques help minimize vibrations and ensure smooth operation of the drive shaft.

4. Universal Joints and Constant Velocity Joints:

Drive shafts often incorporate universal joints (U-joints) or constant velocity (CV) joints to accommodate misalignment and maintain balance during operation. U-joints are flexible joints that allow for angular movement between shafts. They are typically used in applications where the drive shaft operates at varying angles. CV joints, on the other hand, are designed to maintain a constant velocity of rotation and are commonly used in front-wheel-drive vehicles. By incorporating these joints, drive shafts can compensate for misalignment, reduce stress on the shaft, and minimize vibrations that can negatively impact power transfer efficiency and balance.

5. Maintenance and Inspection:

Regular maintenance and inspection of drive shafts are essential for ensuring efficient power transfer and balance. Periodic checks for wear, damage, or misalignment can help identify any issues that may affect the drive shaft’s performance. Lubrication of the joints and proper tightening of fasteners are also critical for maintaining optimal operation. By adhering to recommended maintenance procedures, any imbalances or inefficiencies can be addressed promptly, ensuring continued efficient power transfer and balance.

In summary, drive shafts ensure efficient power transfer while maintaining balance through careful material selection, thoughtful design considerations, balancing techniques, and the incorporation of flexible joints. By optimizing these factors, drive shafts can transmit rotational power smoothly and reliably, minimizing energy losses and vibrations that can impact performance and longevity.

How do drive shafts enhance the performance of automobiles and trucks?

Drive shafts play a significant role in enhancing the performance of automobiles and trucks. They contribute to various aspects of vehicle performance, including power delivery, traction, handling, and overall efficiency. Here’s a detailed explanation of how drive shafts enhance the performance of automobiles and trucks:

1. Power Delivery: Drive shafts are responsible for transmitting power from the engine to the wheels, enabling the vehicle to move forward. By efficiently transferring power without significant losses, drive shafts ensure that the engine’s power is effectively utilized, resulting in improved acceleration and overall performance. Well-designed drive shafts with minimal power loss contribute to the vehicle’s ability to deliver power to the wheels efficiently.

2. Torque Transfer: Drive shafts facilitate the transfer of torque from the engine to the wheels. Torque is the rotational force that drives the vehicle forward. High-quality drive shafts with proper torque conversion capabilities ensure that the torque generated by the engine is effectively transmitted to the wheels. This enhances the vehicle’s ability to accelerate quickly, tow heavy loads, and climb steep gradients, thereby improving overall performance.

3. Traction and Stability: Drive shafts contribute to the traction and stability of automobiles and trucks. They transmit power to the wheels, allowing them to exert force on the road surface. This enables the vehicle to maintain traction, especially during acceleration or when driving on slippery or uneven terrain. The efficient power delivery through the drive shafts enhances the vehicle’s stability by ensuring balanced power distribution to all wheels, improving control and handling.

4. Handling and Maneuverability: Drive shafts have an impact on the handling and maneuverability of vehicles. They help establish a direct connection between the engine and the wheels, allowing for precise control and responsive handling. Well-designed drive shafts with minimal play or backlash contribute to a more direct and immediate response to driver inputs, enhancing the vehicle’s agility and maneuverability.

5. Weight Reduction: Drive shafts can contribute to weight reduction in automobiles and trucks. Lightweight drive shafts made from materials such as aluminum or carbon fiber-reinforced composites reduce the overall weight of the vehicle. The reduced weight improves the power-to-weight ratio, resulting in better acceleration, handling, and fuel efficiency. Additionally, lightweight drive shafts reduce the rotational mass, allowing the engine to rev up more quickly, further enhancing performance.

6. Mechanical Efficiency: Efficient drive shafts minimize energy losses during power transmission. By incorporating features such as high-quality bearings, low-friction seals, and optimized lubrication, drive shafts reduce friction and minimize power losses due to internal resistance. This enhances the mechanical efficiency of the drivetrain system, allowing more power to reach the wheels and improving overall vehicle performance.

7. Performance Upgrades: Drive shaft upgrades can be popular performance enhancements for enthusiasts. Upgraded drive shafts, such as those made from stronger materials or with enhanced torque capacity, can handle higher power outputs from modified engines. These upgrades allow for increased performance, such as improved acceleration, higher top speeds, and better overall driving dynamics.

8. Compatibility with Performance Modifications: Performance modifications, such as engine upgrades, increased power output, or changes to the drivetrain system, often require compatible drive shafts. Drive shafts designed to handle higher torque loads or adapt to modified drivetrain configurations ensure optimal performance and reliability. They enable the vehicle to effectively harness the increased power and torque, resulting in improved performance and responsiveness.

9. Durability and Reliability: Robust and well-maintained drive shafts contribute to the durability and reliability of automobiles and trucks. They are designed to withstand the stresses and loads associated with power transmission. High-quality materials, appropriate balancing, and regular maintenance help ensure that drive shafts operate smoothly, minimizing the risk of failures or performance issues. Reliable drive shafts enhance the overall performance by providing consistent power delivery and minimizing downtime.

10. Compatibility with Advanced Technologies: Drive shafts are evolving in tandem with advancements in vehicle technologies. They are increasingly being integrated with advanced systems such as hybrid powertrains, electric motors, and regenerative braking. Drive shafts designed to work seamlessly with these technologies maximize their efficiency and performance benefits, contributing to improved overall vehicle performance.

In summary, drive shafts enhance the performance of automobiles and trucks by optimizing power delivery, facilitating torque transfer, improving traction and stability, enhancing handling and maneuverability, reducing weight, increasing mechanical efficiency, enabling compatibility with performance upgrades and advanced technologies, and ensuring durability and reliability. They play a crucial role in ensuring efficient power transmission, responsive acceleration, precise handling, and overall improved performance of vehicles.

What is a drive shaft and how does it function in vehicles and machinery?

A drive shaft, also known as a propeller shaft or prop shaft, is a mechanical component that plays a critical role in transmitting rotational power from the engine to the wheels or other driven components in vehicles and machinery. It is commonly used in various types of vehicles, including cars, trucks, motorcycles, and agricultural or industrial machinery. Here’s a detailed explanation of what a drive shaft is and how it functions:

1. Definition and Construction: A drive shaft is a cylindrical metal tube that connects the engine or power source to the wheels or driven components. It is typically made of steel or aluminum and consists of one or more tubular sections with universal joints (U-joints) at each end. These U-joints allow for angular movement and compensation of misalignment between the engine/transmission and the driven wheels or components.

2. Power Transmission: The primary function of a drive shaft is to transmit rotational power from the engine or power source to the wheels or driven components. In vehicles, the drive shaft connects the transmission or gearbox output shaft to the differential, which then transfers power to the wheels. In machinery, the drive shaft transfers power from the engine or motor to various driven components such as pumps, generators, or other mechanical systems.

3. Torque and Speed: The drive shaft is responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). The drive shaft must be capable of transmitting the required torque without excessive twisting or bending and maintaining the desired rotational speed for efficient operation of the driven components.

4. Flexible Coupling: The U-joints on the drive shaft provide a flexible coupling that allows for angular movement and compensation of misalignment between the engine/transmission and the driven wheels or components. As the suspension system of a vehicle moves or the machinery operates on uneven terrain, the drive shaft can adjust its length and angle to accommodate these movements, ensuring smooth power transmission and preventing damage to the drivetrain components.

5. Length and Balance: The length of the drive shaft is determined by the distance between the engine or power source and the driven wheels or components. It should be appropriately sized to ensure proper power transmission and avoid excessive vibrations or bending. Additionally, the drive shaft is carefully balanced to minimize vibrations and rotational imbalances, which can cause discomfort, reduce efficiency, and lead to premature wear of drivetrain components.

6. Safety Considerations: Drive shafts in vehicles and machinery require proper safety measures. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts and reduce the risk of injury in the event of a malfunction or failure. Additionally, safety shields or guards are commonly installed around exposed drive shafts in machinery to protect operators from potential hazards associated with rotating components.

7. Maintenance and Inspection: Regular maintenance and inspection of drive shafts are essential to ensure their proper functioning and longevity. This includes checking for signs of wear, damage, or excessive play in the U-joints, inspecting the drive shaft for any cracks or deformations, and lubricating the U-joints as recommended by the manufacturer. Proper maintenance helps prevent failures, ensures optimal performance, and prolongs the service life of the drive shaft.

In summary, a drive shaft is a mechanical component that transmits rotational power from the engine or power source to the wheels or driven components in vehicles and machinery. It functions by providing a rigid connection between the engine/transmission and the driven wheels or components, while also allowing for angular movement and compensation of misalignment through the use of U-joints. The drive shaft plays a crucial role in power transmission, torque and speed delivery, flexible coupling, length and balance considerations, safety, and maintenance requirements. Its proper functioning is essential for the smooth and efficient operation of vehicles and machinery.

editor by CX 2023-11-09

China Made in China Die Forging Alloy Steel Farm Tractor Spare Parts Drive Axle Yoke Shaft drive shaft yoke

Solution Description

one

Products

Identify: Made in china die forging alloy steel farm tractor spare parts drive axle yoke shaft

Materials: 40CrMo

Excess weight: From .2kg-5kg

Packing: wooden circumstance

Min order: 1000pcs

Custom-made creation is offered as your drawings or sample.

| Method | Die Forging | |

| Content | Stainless Metal, Carbon Metal, Alloy Steel | |

| Weight | 0.1Kg~20Kg | |

| Warmth Remedy | Quenching, Annealing,Tempering,Normalizing, Quenching and Tempering | |

| Testing instrument | composition screening | Spectrometer, Metallographic microscope |

| Performance testing | Hardness tester, Tensile screening device | |

| Size Measuring | CMM,Micrometer, Vernier Caliper, Depth Caliper, feeler gauge | |

| Thread Gauge , Peak Gauge | ||

| Roughness | Ra1.6~Ra6.three | |

| Machining Products | CNC Middle , CNC Machines, Turning, Drilling, Milling, boring machine,Grinding Devices, | |

| Wire EDM,Laser Slicing&Welding, Plasma Slicing &Welding, EDM and so on. | ||

| Top quality management | Sampling inspection of uncooked components and semi-concluded goods, one hundred% Inspection of concluded products | |

| Floor Treatment | Shot Blast , Powder Coating, Sharpening, Galvanized , Chrome Plated | |

| Production Capacity | 60000T / Years | |

| Direct Time | Normally 30 – 45 Times. | |

| Payment Terms | T/T , L/C | |

| Substance Regular | ASTM , AISI , DIN , BS, JIS, GB, | |

| Certification | ISO9001:2008, IATF16949:2016 | |

two

Products Good quality Management

Quality management entail the inspection and management of incoming components, production processes, and completed merchandise.

The quality control method involves,

1 Very first of all, the incoming raw components with random sampling are analyzed by metallographic microscope to make sure that the chemical composition meets the production needs

two Then In the creation method, there are QC staffs timely sampling guarantee that the items are free of defects in the production procedure, and to coordinate and take care of any irregular top quality concerns may be happened.

3 The last step of production process is magnetic particle flaw detector of the metal elements to detect it is hidden crack or other defects.

4 All the completed steel elements is sampled in proportion and despatched to the laboratory for different mechanical functionality tests and measurement measurement, and the area good quality is manually a hundred% inspected.

The pertinent testing products images are as pursuing:

three

Good quality Administration Technique Control:

We strictly have out system administration accordance with iso9001 and ts16949 quality requirements. And 5S lean generation administration is implemented on the production internet site.

The production administration website as pursuing:

4

Our Rewards:

Manufacturer

Our mother or father company, HiHangZhou Team, is a globe-renowned high-conclude equipment producing enterprise with forty domestic subsidiaries and branches and 8 overseas producing vegetation. Has lengthy-term expertise and great reputation in cooperation with world-renowned enterprises.

Technologies

We have a total generation procedure and tools investigation and advancement abilities for ferrous metals forming. More than twenty five many years of manufacturing encounter in forging gear and casting equipment producers, make us a lot more totally get all the overall performance of each gear. 1-3rd of our company’s personnel are technician and R&D personnel, making certain that substantial-quality items are produced with higher performance.

Provider

We can offer customized and normal manufacturing services with multiple production process integrations. The quality and shipping of goods can be entirely certain, and the ability to connect quickly and efficiently.

Society

The unique corporate society can give total engage in to the prospective of men and women and supply a strong vitality for the sustainable improvement of the organization.

Social obligation

Our company strictly implements low-carbon environmental safety, strength-preserving and emission-reduction manufacturing, and is a benchmark company in neighborhood region.

5

Organization Culture

Our Eyesight

To turn out to be 1 of the major organizations

Our Mission

To grow to be a system for employees to recognize their desire

To turn out to be 1 of the reworking and upgrading pacemaker of Chinese enterprises

To set the nationwide brands with satisfaction

Our Perception

Attempt to create the firm into an ideal platform for business owners to understand their self-value and lead to the modern society

Values

Advancement is innovation, absolutely everyone can innovate

innovation inspired and failures tolerated

6

FAQ

1.

Q: Are you a trading organization or a manufacturer?

A: Clearly we are a company of forging products, casting goods and also have a higher level of machining capabilities.

two.

Q: What sequence goods do your have?

A: We are largely engaged in forming processing of ferrous metals, including processing by casting , forging and machining. As you know, these kinds of equipment areas can be noticed in different industries of tools producing.

three

Q: Do you provide samples? is it totally free?

A: Indeed, we commonly offer samples according to the standard apply, but we also require buyers to give a freight shell out-by-account quantity to present mutual sincerity of cooperation.

four

Q: Is OEM available?

A: Yes, OEM is offered.

5

Q: What is your good quality guarantee?

A: We insist that the survival of the organization need to rely on the goods top quality ongoing advancement, with out which we are not able to endure for prolonged. We have out strictly solution quality management for each approach from incoming supplies, production approach to completed products by means of innovative detection instrument and gear. We also invite unbiased 3rd get-togethers to certify our good quality and management methods. Till now we have passed ISO/TS16949 and SGS certification .

6

Q. How about the Packing?

A: We generally use the iron box, or wooden case, also it can be personalized according to customer’s calls for.

7

Q: What is your least get quantity?

A: Sure, we need all intercontinental orders to have an minimal purchase quantity. The amount is up to the actual goods attribute or house such as the substance, fat, construction and so forth.

eight

Q: What is the lead time?

A: Typically our forging goods and casting items want to make new dies or molds, the time of generating new dies or molds and samples in 30-45 times, and the large batch creation time inside thirty-forty five times. it truly is also in accordance to the components structural complexity and amount.

nine

Q: What kinds of payment approaches do you settle for?

A: You can make the payment by T/T or L/C. thirty% deposit in advance, 70% equilibrium from the copy of B/L.

Certification

|

US $3-20 / Piece | |

1,000 Pieces (Min. Order) |

###

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Pressure Casting |

| Application: | Agricultural Machinery Parts |

| Material: | Steel |

| Heat Treatment: | Tempering |

###

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Process | Die Forging | |

| Material | Stainless Steel, Carbon Steel, Alloy Steel | |

| Weight | 0.1Kg~20Kg | |

| Heat Treatment | Quenching, Annealing,Tempering,Normalizing, Quenching and Tempering | |

| Testing instrument | composition testing | Spectrometer, Metallographic microscope |

| Performance testing | Hardness tester, Tensile testing machine | |

| Size Measuring | CMM,Micrometer, Vernier Caliper, Depth Caliper, feeler gauge | |

| Thread Gauge , Height Gauge | ||

| Roughness | Ra1.6~Ra6.3 | |

| Machining Equipment | CNC Center , CNC Machines, Turning, Drilling, Milling, boring machine,Grinding Machines, | |

| Wire EDM,Laser Cutting&Welding, Plasma Cutting &Welding, EDM etc. | ||

| Quality control | Sampling inspection of raw materials and semi-finished products, 100% Inspection of finished products | |

| Surface Treatment | Shot Blast , Powder Coating, Polishing, Galvanized , Chrome Plated | |

| Production Capacity | 60000T / Years | |

| Lead Time | Normally 30 – 45 Days. | |

| Payment Terms | T/T , L/C | |

| Material Standard | ASTM , AISI , DIN , BS, JIS, GB, | |

| Certification | ISO9001:2008, IATF16949:2016 | |

|

US $3-20 / Piece | |

1,000 Pieces (Min. Order) |

###

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Pressure Casting |

| Application: | Agricultural Machinery Parts |

| Material: | Steel |

| Heat Treatment: | Tempering |

###

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Process | Die Forging | |

| Material | Stainless Steel, Carbon Steel, Alloy Steel | |

| Weight | 0.1Kg~20Kg | |

| Heat Treatment | Quenching, Annealing,Tempering,Normalizing, Quenching and Tempering | |

| Testing instrument | composition testing | Spectrometer, Metallographic microscope |

| Performance testing | Hardness tester, Tensile testing machine | |

| Size Measuring | CMM,Micrometer, Vernier Caliper, Depth Caliper, feeler gauge | |

| Thread Gauge , Height Gauge | ||

| Roughness | Ra1.6~Ra6.3 | |

| Machining Equipment | CNC Center , CNC Machines, Turning, Drilling, Milling, boring machine,Grinding Machines, | |

| Wire EDM,Laser Cutting&Welding, Plasma Cutting &Welding, EDM etc. | ||

| Quality control | Sampling inspection of raw materials and semi-finished products, 100% Inspection of finished products | |

| Surface Treatment | Shot Blast , Powder Coating, Polishing, Galvanized , Chrome Plated | |

| Production Capacity | 60000T / Years | |

| Lead Time | Normally 30 – 45 Days. | |

| Payment Terms | T/T , L/C | |

| Material Standard | ASTM , AISI , DIN , BS, JIS, GB, | |

| Certification | ISO9001:2008, IATF16949:2016 | |

Drive shaft type

The driveshaft transfers torque from the engine to the wheels and is responsible for the smooth running of the vehicle. Its design had to compensate for differences in length and angle. It must also ensure perfect synchronization between its joints. The drive shaft should be made of high-grade materials to achieve the best balance of stiffness and elasticity. There are three main types of drive shafts. These include: end yokes, tube yokes and tapered shafts.

tube yoke

Tube yokes are shaft assemblies that use metallic materials as the main structural component. The yoke includes a uniform, substantially uniform wall thickness, a first end and an axially extending second end. The first diameter of the drive shaft is greater than the second diameter, and the yoke further includes a pair of opposing lugs extending from the second end. These lugs have holes at the ends for attaching the axle to the vehicle.

By retrofitting the driveshaft tube end into a tube fork with seat. This valve seat transmits torque to the driveshaft tube. The fillet weld 28 enhances the torque transfer capability of the tube yoke. The yoke is usually made of aluminum alloy or metal material. It is also used to connect the drive shaft to the yoke. Various designs are possible.

The QU40866 tube yoke is used with an external snap ring type universal joint. It has a cup diameter of 1-3/16″ and an overall width of 4½”. U-bolt kits are another option. It has threaded legs and locks to help secure the yoke to the drive shaft. Some performance cars and off-road vehicles use U-bolts. Yokes must be machined to accept U-bolts, and U-bolt kits are often the preferred accessory.

The end yoke is the mechanical part that connects the drive shaft to the stub shaft. These yokes are usually designed for specific drivetrain components and can be customized to your needs. Pat’s drivetrain offers OEM replacement and custom flanged yokes.

If your tractor uses PTO components, the cross and bearing kit is the perfect tool to make the connection. Additionally, cross and bearing kits help you match the correct yoke to the shaft. When choosing a yoke, be sure to measure the outside diameter of the U-joint cap and the inside diameter of the yoke ears. After taking the measurements, consult the cross and bearing identification drawings to make sure they match.

While tube yokes are usually easy to replace, the best results come from a qualified machine shop. Dedicated driveshaft specialists can assemble and balance finished driveshafts. If you are unsure of a particular aspect, please refer to the TM3000 Driveshaft and Cardan Joint Service Manual for more information. You can also consult an excerpt from the TSB3510 manual for information on angle, vibration and runout.

The sliding fork is another important part of the drive shaft. It can bend over rough terrain, allowing the U-joint to keep spinning in tougher conditions. If the slip yoke fails, you will not be able to drive and will clang. You need to replace it as soon as possible to avoid any dangerous driving conditions. So if you notice any dings, be sure to check the yoke.

If you detect any vibrations, the drivetrain may need adjustment. It’s a simple process. First, rotate the driveshaft until you find the correct alignment between the tube yoke and the sliding yoke of the rear differential. If there is no noticeable vibration, you can wait for a while to resolve the problem. Keep in mind that it may be convenient to postpone repairs temporarily, but it may cause bigger problems later.

end yoke

If your driveshaft requires a new end yoke, CZPT has several drivetrain options. Our automotive end yoke inventory includes keyed and non-keyed options. If you need tapered or straight holes, we can also make them for you.

A U-bolt is an industrial fastener that has U-shaped threads on its legs. They are often used to join two heads back to back. These are convenient options to help keep drivetrain components in place when driving over rough terrain, and are generally compatible with a variety of models. U-bolts require a specially machined yoke to accept them, so be sure to order the correct size.

The sliding fork helps transfer power from the transfer case to the driveshaft. They slide in and out of the transfer case, allowing the u-joint to rotate. Sliding yokes or “slips” can be purchased separately. Whether you need a new one or just a few components to upgrade your driveshaft, 4 CZPT Parts will have the parts you need to repair your vehicle.

The end yoke is a necessary part of the drive shaft. It connects the drive train and the mating flange. They are also used in auxiliary power equipment. CZPT’s drivetrains are stocked with a variety of flanged yokes for OEM applications and custom builds. You can also find flanged yokes for constant velocity joints in our extensive inventory. If you don’t want to modify your existing drivetrain, we can even make a custom yoke for you.

editor by czh 2023-01-24

Best supplier made in China – replacement parts – PTO shaft manufacturer & factory 4-40-721 pto drive shaft pin End Yoke with ce certificate top quality low price

We – EPG Group the largest agricultural gearbox and pto manufacturing facility in China with 5 different branches. For more information: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

bush hog slip clutch disc Our versatile pto shaft items 2004 bmw x3 rear drive shaft is pto shafts australia well-known longview generate shaft exported pto shaft for generator to how to get rid of the pto shaft on an 8n ford tractor the 2006 ford explorer entrance drive shaft United 2008 f150 push shaft States, tata nano push shaft Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South The us, Thailand, Pakistan, Indonesia, a lot more than 60 nations around the world and locations. Underneath the assistance of managerial perception of “Serving agriculture, scoring a success by way of high quality of products and honesty in business”, our merchandise have been reliable by consumers and have gained a bigger share of industry. Our firm prodcue all the American tube yoke, flange yoke, weld yoke, center yoke, spline yoke, sip yoke, spline shaft and etc. so if you have fascination for these components, remember to really feel totally free contact us, thank you very a lot progress!!!

| StHangZhourd Part # | Series | Spline | Spline Duration | Tube Dimension | ( R )Hub Diameter | ( K )Stop of Spline to Stage of Weld |

| two-40-1711 | 1280 | one.38″-sixteen | 2.twenty five” | two.50″ x .083″W | 2.34″ | 6.34″ |

| 2-forty-1711 | 1310 | 1.38″-16 | 2.25″ | 2.fifty” x .083″W | two.34″ | 6.34″ |

| 3-forty-1611 | 1350 | 1.fifty”-sixteen | two.fifty” | 3″ x .083″W | two.eighty four” | seven.twenty five” |

| 3-40-1531 | 1410 | one.50″-16 | 3″ | 3.50″ x .083″W | 3.34″ | six.56″ |

| three-forty-1491 | 1410 | 1.50″-16 | three” | three.50″ x .083″W | three.34″ | 7.fifty three” |

| 3-40-1711 | 1410 | 1.56″-16 | 5″ | three” x .083″W | two.84″ | 13.forty one” |

| 3-40-1551 | 1480 | one.fifty six”-16 | 3″ | four” x .083″W | three.84″ | 8.94″ |

| 3-40-1571 | 1480 | one.56″-sixteen | 3″ | 3.50″ x .083″W | 3.34″ | six.75″ |

| 3-forty-1391 | 1480 | one.56″-16 | 3″ | three.50″ x .083″W | three.34″ | eight.seventy five” |

| 4-forty-721 | 1550 | one.seventy five”-sixteen | three” | three.fifty” x .095″W | 3.32″ | nine.22″ |

| four-forty-761 | 1550 | 1.seventy five”-16 | 3″ | 3.50″ x .095″W | three.32″ | 6.78″ |

| 5-forty-1011 | 1610 | 2″-16 | 3.50″ | three.fifty” x .134″W | 3.24″ | nine.69″ |

| 5-forty-1041 | 1610 | two”-16 | 3.50″ | 3.50″ x .134″W | 3.24″ | 10.19″ |

| 5-forty-1191 | 1610 | 2″-sixteen | 3.50″ | 3.fifty” x .134″W | 3.24″ | 7.56″ |

| 5-forty-1051 | 1610 | 2″-16 | three.fifty” | four” x .134″W | 3.seventy four” | 9.84″ |

| six-40-521 | 1710 | two.50″-sixteen | 4″ | 4″ x .134″W | three.seventy four” | 10.fifty six” |

| 6-40-521 | 1710 | two.50″-16 | four” | four.09″ x .one hundred eighty”W | 3.74″ | ten.56″ |

| 6-forty-541 | 1710 | two.50″-16 | four” | 4″ x .134″W | three.seventy four” | 9.twenty five” |

| six-40-541 | 1710 | two.fifty”-sixteen | four” | four.09″ x .a hundred and eighty”W | 3.74″ | 9.25″ |

| 6-forty-621 | 1710 | 2.fifty”-sixteen | 4″ | 4.50″ x .134″W | four.24″ | 10.sixty five” |

| 6-40-631 | 1710 | 2.50″-sixteen | 4″ | 4.50″ x .134″W | four.24″ | nine.fifty” |

| six-forty-711 | 1710 | two.fifty”-sixteen | four” | four” x .134″W | three.seventy four” | eight.44″ |

| six-forty-541 | 1760 | 2.fifty”-16 | four” | four.06″ x .a hundred sixty five”W | three.seventy four” | nine.twenty five” |

| 6.5-40-191 | 1810 | three”-sixteen | 4.50″ | 4.fifty” x .134″W | 4.24″ | eleven.twenty five” |

| six.5-forty-201 | 1810 | three”-sixteen | 4.50″ | four.50″ x .134″W | 4.24″ | 9.47″ |

| 8-40-ninety one | 1810 | three”-sixteen | 4.fifty” | 4.50″ x .259″W | 4″ | nine.91″ |

| 8-forty-one zero one | 1810 | 3″-sixteen | four.fifty” | four.fifty” x .259″W | 4″ | eleven.fifty three” |

| eight-40-91 | 1880 | three”-sixteen | four.50″ | four.50″ x .259″W | four” | nine.ninety” |

| 8-40-one hundred and one | 1880 | three”-sixteen | four.50″ | four.50″ x .259″W | four” | 11.fifty three” |

| 9-42-311 | 1950 | four.167″-24 Inv. | six.fifty” | 5.twenty five” x ,375″W | four.fifty” | 13.47″ |

| nine-42-421 | 1950 | 4.167″-24 Inv. | 6.fifty” | six” x .500″W | 5.fifteen” | 13.47″ |

| nine-42-281 | 2050 | 5.835″-34 Inv. | nine.50″ | 8″x .375″W | 7.38″ | fourteen.50″ |

| nine-forty two-351 | 2050 | 5.835″-34 Inv. | nine.50″ | 8″x .375″W | 7.38″ | sixteen.60″ |

| nine-42-301 | 2150 | five.835″-34 Inv. | twelve” | nine”x .625″W | eight” | 19.sixty three” |

China manufacturer & factory supplier for drive in Shiraz Iran shaft Tube Weld Yoke With high quality best price & service

industrial components like roller chains. Roller chains are obtainable in common, nickel plated & stainless metal components in pitch dia. ranging from 1/4 in. to 3 in. Varieties consist of leaf chains in lacing configurations ranging from 2 x 2 to 8 x 8. Leaf chains are obtainable in pitch measurements ranging from 1/2 in. to 2 in., pin dia. ranging from .156 in. to .687 in. & tensile strengths ranging from 4,000 lbs. to 156,000 lbs. Applications include agricultural, conveyors, drilling, electronics assembly, foodstuff processing, fork raise vehicles, hoists, packaging & textile equipment.Our business pays specific consideration to customers’ demands, listening to the specific requirements of every single consumer and guaranteeing overall satisfaction.

Overview

Rapid Information

- Applicable Industries:

-

Manufacturing Plant

- Place of Origin:Zhejiang, China

- Brand name Identify:

-

OEM

- Type:

-

Driveshaft

Source Ability

- Offer Capability:

- 5000 Piece/Pieces per Week

Packaging & Delivery

- Packaging Particulars

- Neutral packing.

- Port

- Shang hai/Ning bo

-

Lead Time

: -

Quantity(Parts) one – one hundred one zero one – 1000 1001 – 10000 >10000 Est. Time(days) 15 30 forty five It is wise to pay consideration to this aspect when the equipment redSlip clutch type on the rotary tiller, again slight oozing of grease on the UJ, do not grease the clutch these operate dry and need to be “slipped” at the very least when a 12 months to avoid rusting togetherucer output shaft is driven as an alternative of becoming a driver. Bearing in thoughts that one particular of the features of this worm-gear reducer is the truth that are not able to be axle-driven by the output shaft (irreversibility), it is almost extremely hard to meet overall irreversibility conditions, because of to external aspects such as vibrations, etcÖ This is why, when the software requires whole irreversibility, it is recommended to make use of external brakes with ample power to keep away from slipping.

To be negotiated

On-line Customization

Hangzhou Ever-Electrical power Transmission Co., Ltd. (Member of At any time-Electrical power Group ) is a expert in making all varieties of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm gearboxes, in-line helical equipment speed reducers, parallel shaft helical equipment reducers, helical bevel reducers, helical worm equipment reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, PTO shafts, specific reducer & relevant equipment elements and other related merchandise, hydraulic cylinder, equipment pumps and so on. Additionally, we can generate tailored variators, geared motors, electrical motors and other hydrauOur items is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, more than 60 countries and regions.lic goods in accordance to customers’ drawings. Our revenue value in yr 2007 was more than Euro 50 Million. We personnel above 1500 employees, and have CNC turning machines and CNC operate centers. For far more specifics, make sure you check out our device lists.

Hangzhou Ever-Electrical power Transmission Co., Ltd. (Member of At any time-Electrical power Group ) is a expert in making all varieties of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm gearboxes, in-line helical equipment speed reducers, parallel shaft helical equipment reducers, helical bevel reducers, helical worm equipment reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, PTO shafts, specific reducer & relevant equipment elements and other related merchandise, hydraulic cylinder, equipment pumps and so on. Additionally, we can generate tailored variators, geared motors, electrical motors and other hydrauOur items is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, more than 60 countries and regions.lic goods in accordance to customers’ drawings. Our revenue value in yr 2007 was more than Euro 50 Million. We personnel above 1500 employees, and have CNC turning machines and CNC operate centers. For far more specifics, make sure you check out our device lists.

Tube Weld Yoke

Best China manufacturer & factory Widely in Orumiyeh Iran Used Durable Cardan Shaft Tractor Splined Yoke With high quality best price

High quality and credit history are the bases that make a corporation alive. a specialised supplier of a entire variety of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Swift Details

- Guarantee:

-

1.5 several years

- Relevant Industries:

-

Production Plant

- Following Guarantee Provider:

-

On the internet support

- Neighborhood Service Location:

-

none

- Showroom Spot:

-

ITALY

- Location of Origin:Zhejiang, China

- Brand Identify:

-

OEM

- Regional Provider Location:

-

Italy

- certificate:

-

CE

- Materials:

-

Metallic

- Processing of yoke:

-

Forging

- Style:

-

Customized

- Certificate:

-

CE Certification

Source Ability

- Supply Capability:

- 80000 Piece/Pieces per Thirty day period

Packaging & Shipping and delivery

- Packaging Particulars

- Normal export packing

- Port

- NINGBO OR SHANGHAI

Online CustomizatThe business masking 88,000 square meters, has advanced equipment Buyer Focused EPG thinks in engineering high quality interactions with our consumers that reinforce what we can achieve together. Our company and the folks inside our enterprise are dedicated to developing lengthy long lasting partnerships that are as trustworthy as our goods and as easy as our services.and strong complex strength, these kinds of as the numerical management machine tools and machining facilities, CAD/CAM program, industrial robot and so forth. ion

Product Data

Merchandise Details

PTO Shaft

The energy take-off (PTO) is a advanced system, allowing implements to draw power from the motor and transmit it to yet another application. It operates as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The energy just take-off shaft (PTO shaft) is a critical part, made and created for constant hefty-duty use. A very good PTO shaft need to be strong sufficient to bear the torsion and shear pressure and lessen vibration.

Setforge, the forging subsidiary of Ever-Energy Team, manufactures chilly extruded PTO shafts for all kinds of agriculture vehicles. Our PTO shafts provide wonderful dependability and longevity during day-to-day use.

EP Group has been internationally identified as a dependable world-wide provider. Our state-of-the-artwork production procedure and experienced engineers make certain the prime-top quality of all Farinia parts.

| After Guarantee Service | Video specialized help |

| Applicable Industries | Producing Plant |

| Regional Services Spot | Italy |

| Showroom Spot | Italy |

| Warranty | 1.5 several years |

| Location of Origin | China |

| China | Zhejiang |

| Manufacturer Title | EPG |

| certification | CE |

| Materials | Steel |

| Processing of yoke | Forging |

| Style | Custom-made |

| Certification | CE Certificate |

Solution Screen

Product Display

Industrial-Obligation Ro …

Tie Rod Cylinder H …

Agricultural Gearb …

CompanyInfo

Organization Profile

At any time-Electrical power Team